Key Terms and Abbreviations in Procurement

Explore the key terms, abbreviations, and acronyms in procurement. The Procurement Glossary gives short and simple answers for procurement professionals.

Download guideEnglish

Updated: Nov 27, 2025

Terms used in procurement can be pretty complex. There are many concepts to familiarize oneself with. We have listed key terms and abbreviations in procurement to keep your professional vocabulary up to date.

The glossary provides an overview of the most common terms used in procurement, logistics, supply chain management, and finance. It is a valuable reference for procurement leaders explaining activities to other stakeholders or professionals looking to grow into a role in procurement.

The Procurement Glossary

A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W

A

Absorption costing

In absorption costing the variable and fixed costs are allocated to all units produced during the period. In absorption costing, both direct and indirect costs are taken into account. Different methods are used to allocate indirect costs or overhead to the products.

Accounts payable

A company's liabilities (accounts payable) are what it owes to suppliers and service providers (vendors) for deliveries or services already performed. Subareas of accounts payable are, for example, also document processing, invoice verification, and posting procedures.

Accounts payable automation

By using automated accounts payable (AP automation), companies can manage vendor invoices step-by-step in a digital workflow with no manual work.

Acquisition cost

Acquisition costs are expenses or costs incurred to acquire an asset and bring it to an operational state. Incidental acquisition costs include expenses for transport, installation, and assembly.

Activity-based costing (ABC)

Activity-based costing aims to plan, control and allocate overhead costs. The costs-by-cause principle applies here. After a detailed list of company processes, an exact calculation of each individual product can be made.

After-the-fact purchase order

An after-the-fact purchase order (PO) is used when a requisition and purchase order is being issued after the transaction has occurred and when the transaction doesn’t fit the limited requirements of a payment request form.

Agile procurement

Agile procurement is the ability to react to supply and demand changes in sourcing activities. Agile procurement often relies on lean-agile workflow methods popularized by just-in-time productions and software development. For more information, see "Kaizen" and "Kanban."

Agile spend management

Agile spend management is a framework for controlling 3rd party costs in business using tools, automation, and workflows in an iterative and streamlined way. It achieves this by accelerating time-to-insights and best practice sharing through a proactive and transparent spend culture, where manual processes and bottlenecks are removed, and collective buying expertise is leveraged.

Approved supplier

An approved supplier is checked by the purchasing managers using various criteria. Specific (minimum) standards regarding delivery capability, delivery times, quality, service, ESG standards, and cost commitments must be met to become an approved supplier. Buyers use (web-based) approved supplier lists (ASL).

Auction in procurement

The purchasing department initiates a procurement auction. Competing sellers or suppliers bid for to be auctioned goods, services, etc. There are several auction methods, including "Japanese" (reverse), "Dutch" (falling prices), and "English" auction (classic upside auction).

B

Back order

Dispatch of the currently available products now and delivery of the remaining goods as soon as they are available again in the supplier's warehouse.

Balanced scorecard

A balanced scorecard is a strategic performance management framework to identify and improve various functions, including financial and non-financial metrics. The framework is developed by Robert S. Kaplan and Dave P. Norton. A balanced scorecard in procurement helps managers and teams keep track ofactivities' execution and the consequences of these actions.

Barter

A barter deal in which goods or services are exchanged for another good or service. Money does not flow. Example of a barter deal from the purchasing department of a football club: a beverage supplier provides a certain amount of drinks for the VIP area during home matches and, in return, receives perimeter advertising.

Benchmarking

Benchmarking enables reliable internal and external comparisons based on key figures. The information thus obtained leads to professional evaluations, conclusions, and trend determination. Examples of procurement benchmarking are market benchmarking, where material purchase prices are compared to market indexes, and peer benchmarking, where procurement performance metrics are compared to other similar organizations.

Best alternative to a negotiated agreement (BATNA)

The best alternative to a negotiated agreement (BATNA) refers to the best alternative option if no agreement can be reached during the negotiations. Creating such alternatives beforehand strengthens one's negotiating position and protects against unintentionally exceeding or falling below an internally defined threshold.

Best and final offer (BAFO)

The best and final offer (BAFO) is a technique used in multi-stage negotiation processes. After bidders have submitted their proposals and the scope of work has been agreed upon, they are asked to submit a final offer without room for further negotiation.

Best-of-breed

With best-of-breed, buyers choose, in their opinion, the "best" individual software tools to suit their needs instead of a full-suite solution, a complex application solution from a single manufacturer or technical service provider. For an alternative approach, see "full suite."

Bid

A bid is a price offer for a product or service typically seen in an auction. In procurement, competitive bidding solicits the best price, quality, and terms for purchased goods or services.

Bill of lading

The bill of lading (ship waybill) is a maritime trade document issued by a carrier. It confirms that the goods have been received.

Bill of materials (BOM)

A bill of materials (BOM) is a detailed list of all the raw materials, components, and assemblies needed to create a product. From a procurement perspective, a bill of materials is a useful reference as it documents the ideal item and quantities required to produce the goods.

Blanket order

A blanket (purchase) order is a long-term agreement between the company and a supplier. The business partner delivers materials, goods, products, or services over a certain period (several times) at a fixed price.

Bottleneck item

In procurement, the bottleneck refers to a weak spot where high potential supply risk may occur. Identifying these organizational weaknesses early is essential to avoid interruptions in the production or supply of key products or services. For further information, please refer to "Kraljic Matrix" or learn more about category management and supplier segmentation.

Bottom line

By definition bottom line is the last line of a financial statement. In a procurement context, bottom-line impact refers to results that can be linked directly to financial performance, such as cost savings achieved within a specific financial period.

Breach of contract

A breach of contract occurs when one party has not fulfilled part of a valid agreement. This may result in a partial or complete breach of contract. In this case, compensation clauses apply.

Business process outsourcing

Companies outsource certain non-business critical tasks of the secondary sector to external service providers to focus on their core business. For instance, payroll, accounting, HR, customer care, IT, and logistics can be outsourced.

Business unit

Companies can run separate business units as independent departments, divisions (or isolated businesses) within the parent company or group, and sometimes as a profit center.

Buyer

The buyer (purchaser) is responsible for the systematic, timely satisfaction of the company's (or the internal users') needs - for example, with trade goods, production materials, raw materials, operating materials, and services. In larger companies, buyers are separately concerned with operational and strategic tasks.

C

Capital expenditure (CAPEX)

Capital expenditures (CAPEX) are expenses used to buy, maintain, or improve fixed assets, such as buildings, vehicles, and land. CAPEX investments often require strategic and long-term focus from procurement since they obtain high value and risk of failure.

Carbon accounting

Measurement and management of carbon emissions across all organizational activities. This accounting is crucial for reporting, reducing, and managing carbon emissions.

Carbon disclosure

Reporting of carbon emissions to stakeholders, affecting procurement by influencing supplier selection based on carbon performance.

Carbon footprint

Total carbon emissions produced directly and indirectly by an organization’s activities or products, including the manufacturing, transportation, and disposal of products and services.

Carbon offset

Investments in environmental projects to compensate for emissions from procurement activities, helping achieve carbon neutrality.

Cash flow statement

A cash flow statement is intended to make all company cash flows transparent. This involves quantifying possibilities and making visible reasons for deviations or changes in liquidity.

Catalog

Electronic catalogs bring together demand (usually so-called C-articles) and offers. This reduces time, effort, costs, and maverick buying (uncontrolled procurement bypassing the purchasing department). Larger companies work with their catalogs (buy-side catalogs). These catalogs list approved, recommended, and mandatory items to be ordered. In sell-side catalogs, suppliers combine their offers. Information is standardized and made available to e-procurement systems for further processing. Purchasing can also have its assortments maintained on "external" catalog platforms or can optionally view or use "free" offers.

Categorization

Categorization is the activity of categorizing items into a pre-defined order, such as a hierarchy or taxonomy. In procurement, spend classification categorizes 3rd party costs into a taxonomy, such as the UNSPSC, to identify potential savings and value creation opportunities.

Category in procurement

In procurement, a category is a group of related goods or services with similar characteristics. Examples of categories are packaging, IT, and transportation. Category management is the active control of costs and suppliers within strategic categories.

Category management

Category management in procurement is the segmentation of spend into groups of similar goods or services in order to identify potential value creation opportunities.The value of category management often comes from so-called economies of scale, where spend across an organization can be consolidated into a smaller number of strategic supplier relationships, leading to lower costs and better quality control. In larger companies, dedicated Category Managers are domain experts for managing spend in specific strategic categories.

Center of excellence

Companies set up a competence center to drive forward complex projects of great strategic relevance (e.g., transformation, digitization, innovation) by a team of experts within a specific time frame. Best practices are developed.

Centralized procurement

Centralized procurement controls the spending of decentralized purchasing units at all regional and national locations in one department - usually at the company headquarters. Advantages include better conditions through volume bundling, targeted utilization of warehouse capacities, reduced logistics costs, standardized personnel development, and a better overview of suppliers.

Certificate of origin (COO)

The certificate of origin (also: proof of origin) is used in international goods traffic as an official confirmation of the origin of a product.

Change order

Utilizing resources while reduction, reuse, and recycling of elements prevails. Procurement emphasizes obtaining goods and services in a way that extends the lifecycle of resources, minimizes waste, and reduces environmental impact.

Circular Economy

Often the requirements of the purchasing department change during the order execution. Minor quantitative changes can be handled using supplements. In the case of more extensive adjustments, it must be clarified whether the changes can be controlled via existing contracts or whether a new tender must be issued.

Commodity prices

Commodities are basic resources such as food, energy, and metals that can be exchanged for goods of the same type. Procurement organizations actively track and leverage commodity price information to negotiate competitive prices for bought raw materials, goods, or services. Learn more about commodity price fluctuations.

Competitive bidding

By means of electronic tenders, companies are seeking the cheapest or best provider for their lots to be awarded. This can be done as an open bid (all offers visible to competitors) or a sealed bid (usually only one offer by competitors).

Compliance in procurement

Compliance is acting according to defined rules such as laws or standards. In procurement, contact compliance measures whether spend is actively managed through agreed contracts with approved suppliers.

Consignment

Delivery (also: shipment). Transfer of material, product, or goods; legal ownership is only transferred through sales.

Continuity plan

A continuity plan is designed to ensure that a company can maintain its performance even in the event of a crisis. As part of risk management, strategies and processes are proactively aligned in order to be able to react quickly and adequately in the occurrence of damage.

Contract lifecycle management

For procurement teams, contract lifecycle management is the proactive control of supplier relationships and performance through the strategic use of contracts. To start, digitalized contracts are stored in one location across the whole organization. With all contracts stored in one place, central or local procurement teams can refine and standardize contract terms across suppliers, categories, and business units. Through digitalized contract lifecycle management procurement teams can be notified which strategic contracts are up for renewal and identify and reduce purchases made outside of agreed contracts.

Contract management

Contract management is creating, executing, and analyzing contracts with suppliers, partners, customers, and employees. Organizations with tens or hundreds of thousands of contracts develop formal contract management processes to maximize operational performance while minimizing financial risk. Contracts are an undervalued area for digital transformations. For too many businesses, contracts are still mostly printed on paper, filed, and forgotten after signature. Contract management software allows organizations to centrally store, review and control contracts as a strategic resource across different teams or business units.

Corporate social responsibility (CSR)

Corporate social responsibility (CSR) is a management approach that aims to play a positive role in the surrounding society by considering the environmental and social impact of business decisions and relationships.

Cost analysis

The cost analysis should show which costs (cost elements) are incurred by which cost centers (cost units) - and, above all, what the spend is used for. Among other things, the following are to be analyzed: direct costs, overhead costs, variable costs, fixed costs, secondary costs, planned costs, and part costs.

Cost avoidance

Cost avoidance is any action taken to avoid future costs. In procurement, these are often referred to as "soft savings" because they can't be measured as "hard savings" or cost reductions reflected in financial statements.

Cost center

The place where costs are incurred, and the service is provided. It refers to areas of responsibility, spatial, functional, organizational, or allocation factors.

Cost modeling

When modeling costs, a future cost and revenue situation (e.g., for an innovative product to be developed) can be simulated. Estimates relate, among other things, to material input, machine hours, personnel costs, and other necessary expense items. The modeling software also generates historical data for production and project scenarios and possible future pricing.

Cost of goods sold (COGS)

Cost of sales (essential key figure) refers to costs directly related to the goods and services produced = Cost of sales in the cost-of-sales method.

Cost reductions

Cost reduction is the process of identifying and removing unnecessary costs by companies with the goal of improving profitability. Procurement functions in larger companies are typically tasked with achieving measurable cost savings on 3rd party managed costs.

Credit note

A credit is booked as a positive entry on the account's credit side. This refers to all incoming payments, bank transfers, or amounts collected from another account by direct debit.

Credit rating

A rating checks the creditworthiness of a company, financial instrument, or even a person. Rating agencies or credit institutions usually make classifications.

D

Data cleansing

The process of fixing or removing incorrect, corrupted, incorrectly formatted, duplicate, or incomplete data within a dataset. Vital to maintain accurate and up-to-date vendor information, transaction records, and compliance documentation.

Data enrichment

During data refinement, rudimentary data records are corrected, updated, and enriched with additional information. Departments such as purchasing, sales, and marketing access standardized data and can thus control more effective communication with suppliers and customers.

Data governance

Overall management of the availability, usability, integrity, and security of data used in an organization. In procurement, this involves policies and processes that ensure data is consistent, trustworthy, and does not get misused.

Data integration

The strategic process of consolidating data from several sources to create a cohesive dataset, resulting in a unified view that supports business intelligence and decision-making.

Data visualization

Using visual elements like charts, graphs, and maps, data visualization tools provide an accessible way to see and understand trends, outliers, and patterns in data.

Decentralized procurement

Decentralized procurement takes place in individual departments or at other locations. Its advantages are short distances and exploiting "regional special offers," but it does not involve meaningful bundling via framework agreements with quantity discounts and does not provide an overview of suppliers.

Demand management

Demand management is the process of planning and forecasting the demand for goods or services in a supply chain. Demand management aims to ensure efficient production and predictable cash flow needs.

Digital transformation

Digital transformation in procurement uses digital technologies to change how procurement operates to meet changing business and supply market requirements. Digital transformation includes three equally important areas: processes, tools, and organizational culture.

Digitalization

Digitalization in procurement is a sub-area of digital transformation where procurement information is converted into a digital form that can be processed, analyzed, and shared. An example of digitalization is the conversion of metadata from paper contracts and documents into digital formats.

Direct labor costs

Wages and salaries are considered direct labor costs. In contrast, non-wage labor costs are indirect labor costs.

Direct material costs

Direct material costs come from raw materials and components used to create products. In manufacturing, the management and forecast of direct material costs is a major value driver for procurement.

Direct procurement

Direct procurement is acquiring materials, goods, and resources for production. Direct spend in procurement refers to goods and services directly related to making products. Examples of direct costs categories may include raw materials, machinery, and labor costs directly linked to production.

Diversity

Diverse procurement encourages companies to include minority-owned, underrepresented businesses in their supply base. Organizations classify diverse suppliers in various ways.

Diverse supplier

A diverse supplier is at least 51% owned and managed by an individual or group that is part of a traditionally underrepresented or underserved group. Common classifications include small-business enterprises (SBEs), minority-owned enterprises (MBEs), and woman-owned enterprises (WBEs).

Dutch eAuction

An appropriate auction form when the buyers want to put pressure on bidders: a Dutch procurement auction starts with a low starting price based on advance information to the bidders. This is increased by the buyer in time and price intervals. The first supplier to accept the price currently displayed is awarded the contract.

Dynamic discounting

Dynamic discounting is a service for a buyer. Both buyer and the seller determine discounts automatically applied in case of early payment. Buyers can flexibly decide from case to case which invoice they want to release for early payment.

E

eAuction

Online auctions are used to negotiate and determine market prices for given objects based on individual price limits set by the participants. The purchasing department can use the following types of auctions: English auction (also: open or "descending-bid auction"; here, the bids of the suppliers are successively lowered starting from a high starting price), Dutch auction (also: "Ascending-bid auction; begins with a very low starting price, which is successively increased until the first supplier accepts the bid), First-price sealed-bid auction (a one-off sealed-bid auction in which the bids are submitted once and the supplier with the lowest bid is awarded the contract), Japanese auction (the bid falls from the starting price at certain intervals until only one supplier is prepared to deliver for the price offered).

EBITDA

EBITDA is the abbreviation for earnings before interest, taxes, depreciation, and amortization and means earnings before interest, taxes, depreciation of fixed assets, and amortization of intangible assets.

Economic order quantity

With the optimum order quantity, the sum of the ordering and storage costs for a given service level in the planning period is as low as possible.

Enterprise resource planning (ERP)

When planning business processes, areas such as material, IT, personnel, and also necessary operating resources are managed, planned, and administered according to requirements. Business applications and operating data are stored or processed in a central database, an ERP system.

e-procurement

Electronic procurement is the generic term for the purchase of products and services via digital networks or platforms. With the help of integrated systems and tools, buyers can carry out operational and tactical tasks (such as catalog procurement, auctions, and tenders). Some tools also provide support for strategic objectives.

Equity

The equity capital of a company (positive difference between assets and liabilities) is available to the company or the owner or shareholder as net assets.

Escalation clause

Purchasing and suppliers can define an escalation clause (as an annex to contracts). To be able to clearly define rights and obligations in the event of an escalation, it is important to clearly name all conflicts that could arise from the main contract. The clause should also describe the procedure and sequence (escalation level).

e-sourcing

E-sourcing supports the web-based handling of strategic steps, such as supplier identification, negotiations, auctions, awarding of contracts, and the conclusion of contracts, ultimately finding the right supplier. See also "Sourcing".

e-tendering

In e-tendering, buyers from companies and public institutions (here: e-tendering) tender their requirements or lots on the market in electronic form. Suppliers submit bids within a previously defined period. Both sides save time and effort. The purchasing department hopes to get the best price or supplier. The exchange of information is (system-supported) paperless.

Exchange rate

The exchange rate (also: foreign exchange rate) regulates the price of exchanging a domestic currency for a foreign one (and vice versa; nominal exchange rate).

Expedite

In expediting, experts (expeditors in purchasing and project management) ensure quality and punctual delivery of goods, components, and products. Required goods must arrive at the agreed time and place and specified quality.

Exposure

Another word for risk in finance. Investors are exposed to volatilities in interest rates, exchange rates, or ratings. A default of a bank is also a (high) exposure.

External stakeholders

External stakeholders do not belong to the company but are affected by its strategies and actions. These include suppliers, customers, creditors, and investors.

F

Fair market value

Fair market value (also: appropriate value) is the value attributed to an economic object (such as a share) on the market by the market participants - regardless of the current stock exchange or trading value. Valuation models form the basis.

Financial year

Also: fiscal year, financial year, tax period.

Finished goods

Manufactured goods that are ready for sale or dispatch by the producer; stocks of finished goods are goods that their producer does not intend to process further before dispatch (even if they are intended as inputs for other production processes).

First in first out (FIFO)

Assets that are stored first in the warehouse are also dispatched first.

Fixed assets

Real existing and physically tangible material goods, such as machinery and equipment, land and buildings, office and factory equipment, IT systems, and software. For comparison, intangible fixed assets: distribution rights, licenses, patents that lack physical existence.

Fixed price

Buyers and suppliers can agree on a fixed price (in the contract) for goods, products, or services to be delivered - this price is then neither undercut nor exceeded.

Force majeure

Force majeure occurs when a company cannot meet its production or delivery commitments due to an unforeseeable and unavoidable event. Such an event is beyond the company's control. This includes natural disasters (earthquakes, floods, storms, volcanic eruptions, etc.), fires, blockades, boycotts, embargos, strikes, and wars, for instance.

Forecasting in procurement

Forecasting is the process of making predictions based on past and present data. In procurement, spend forecasting is the estimation of future spend in order to predict demand and cost changes.

Full container load (FCL)

A full container load is a sealed door-to-door transport of the entire container. Partial container loads stand for less than container load.

Full-suite

In the context of procurement, a full-suite refers to a single software solution covering the full strategic sourcing or source-to-pay process. See "best of breed" in this glossary for an alternative approach.

Full-time equivalent

The full-time equivalent (also: full-employee equivalent) defines the number of hours worked divided by the usual working time of a full-time employed person, for example, 40 hours.

Full truck load (FTL)

In the (international) forwarding business, FTL refers to a complete load of a truck which is collected from a single shipper and transported directly to a recipient without transshipment or storage.

G

GenAI in procurement

Use of AI technologies that automate and enhance various procurement functions. It can automate repetitive tasks like purchase order generation and streamline complex activities like supplier risk analysis.

Global sourcing

Within the company, global procurement can be understood as purchasing on international markets (e.g. in low-wage countries) or as more complex strategic actions in other countries (on global procurement markets, cooperation with suppliers).

Go-live

After various test steps within an implementation phase (which usually takes longer), a new tool is released. This means that various employees jointly use the new solution as a productive system after the starting signal.

Goods

Merchandise sold, bought, traded, or exchanged.

Green procurement

In green procurement (also: sustainable procurement, environmentally friendly, or ecological procurement), products, materials, goods, and services are assessed from the point of view of environmental compatibility. The contracting authorities provide binding framework conditions.

Group purchasing organization (GPO)

As the organizational unit of a corporate group, the purchasing organization is responsible for all purchasing processes in the company, negotiates procurement, and develops strategies.

Guarantee

The manufacturer's guarantee means its direct contractual obligation to provide a warranty to the buyer, purchaser, or end user. See also "warranty."

H

Harmonization

Harmonization means, for example, that numbers are unified using a newly defined method. For example, by implementing a software solution for Spend Analysis, all data available throughout the company can be consolidated, validated, and presented transparently and in a user-friendly way. Different supplier number ranges and commodity group systems are harmonized and referenced.

Hedge

Designates a financial hedge against risks - to compensate for fluctuations in interest rates, prices, or exchange rates. A hedger couples a transaction (which must be hedged) with another transaction intended to neutralize the risk, such as futures, options, and forwards.

I

Incoterms

International Commercial Terms. Incoterms are globally applicable standards for delivery terms in international transactions. They regulate the rights and obligations of buyer and seller in connection with the delivery of goods: when the goods are transferred from the seller to the buyer, who bears what transport costs, who assumes liability for loss of and damage to the goods, and insurance costs, and from then on. Some things are not regulated by Incoterms, for example, terms of payment, transfer of ownership of goods, and settlement of disputes. The updated Incoterms are valid from 1 January 2020 and are to be used instead of the Incoterms® 2010 version.

Incumbent supplier

Existing Supplier.

Index pricing

Index-based pricing is a mechanism for price determination for buyers and suppliers. Index pricing is used for example to act more securely in volatile markets, protect margins, and hedge longer contracts transparently.

Indirect procurement

Purchasers in indirect procurement deal with goods, merchandise, and services that are not directly related to the manufacturing of products (also: non-production material). It is important to maintain and further develop the business. Examples of indirect procurement categories:

- Marketing services (media buying, agencies, etc.)

- Consultant services

- Travel services

- MRO (maintenance, repair, and operation)

- IT (hardware, software)

- HR (Recruitment, training, and further education)

- Transport and fleet management

- Supply (gas, electricity, water)

Insourcing

Reintegration of certain tasks, processes, or entire company divisions that had been transferred to service providers or suppliers for external fulfillment. See also "outsourcing."

Intangible cost

Expenditure on intangible assets in the enterprise, such as services and rights.

Integrated procurement system

Optimizes cross-interface process flows in purchasing (and for certain internal users).

Intellectual property

Intellectual property rights; "IP rights" as industrial property rights refer to patents, utility models, designs, trademarks, etc. In the case of cultural property rights, reference is made to copyright law; the personal intellectual creation of the author is protected. Individual industrial property rights are regulated in the respective special protection laws.

Interest rate

The "price" of money.

Internal stakeholders

Internal stakeholders (also: stakeholders, internal "customers") include parties who belong to a company or an organization, such as owners, managers, and employees of other departments. See also "external stakeholders."

Inventory management

Managing and monitoring the flow of goods into and out of the warehouse. One inventory management method is Just-in-time, which is based on low stocks at lower costs.

Inventory management system

Software and processes for professional warehouse management.

Invoice reconciliation

Invoice comparison or verification. In this case, all invoices secured by orders are compared with the order, such as quantity, unit of measurement, and total price. Consistent invoices are (automatically) released for payment.

Invoice-to-pay (I2P)

I2P typically begins with the receipt of an invoice and goes through various steps, from review and approval to payment.

J

Japanese Auction

In the Japanese auction, no bids are initially submitted by suppliers. The starting price, set by the buyer, falls at certain intervals until only one supplier is willing to deliver for the price offered. This ends the auction.

K

Kaizen

Kaizen is the Japanese business philosophy of continuous improvement where all employees are engaged with improving productivity. Kaizen is an aspect of lean-agile workflow methods.

Kanban

Kanban is a way of visualizing work popularized by the lean-agile workflow methods. Originally developed for just-in-time manufacturing in Japan, Kanban has become popular in complex projects in software development and procurement project management.

Key performance indicators (KPIs)

Central performance indicators for updating and comparing a degree of fulfillment of essential functions/results; in purchasing e.g: Purchasing costs as a percentage of purchasing volume, purchasing volume per purchasing employee, adherence to delivery dates, and complaints rate. Here's a complete list of KPIs in procurement.

Kraljic Matrix

The Kraljic matrix is a portfolio view. It can be used by the purchasing department as a basis for procurement strategies. Procured materials and products of a company can be graphically displayed by their supply complexity and their influence on the operating result. There is a distinction between four display or analysis fields: strategic articles, bottleneck articles, leveraged articles, and non-critical articles. Robert Kraljic first described the system in 1983 in an article in the Harvard Business Review.

L

Landed costs

Expenses for the purchase price (per unit), freight, insurance, duties, fees, taxes, and delivery costs (and other costs) to destination (e.g., harbor).

Last in first out (LIFO)

Depositing procedure in the warehouse: Products that were last deposited are the first to be dispatched or consumed.

Late tender

Tender (offer) received after the deadline for submission of tenders.

Lead time

Total time needed from order to transport to receipt and inspection of the goods or service.

Lean manufacture

Lean manufacturing aims at increasing productivity, product quality, and flexible business processes. Factors: flat hierarchies or administration, quick adaptability, avoidance of waste, etc.

Lean procurement

A purchasing organization designed according to lean principles; includes strategy, processes, organization, and employees. The goals of lean procurement are finding and implementing best practices, automated workflows, eliminating duplication of work and non-value-adding activities, avoiding waste, etc.

Letter of credit

The letter of credit is a contractual obligation of a bank to make a payment on behalf of the customer.

Letter of intent

A letter of intent is the first written agreement before the contract is defined in detail.

Lifecycle assessment

A method evaluating environmental impacts of a product’s life stages, guiding procurement decisions to reduce ecological damage.

Liability

To be liable for something.

Licensing

Granting or obtaining permission to produce or use something that another company or person has created or produced and holds the rights.

Life cycle costs

Calculation of life cycle costs from the development of a product to its return - "from the cradle to the grave."

Linear pricing

Same price for each unit of the product. Opposite of non-linear pricing structure, where the prices are based on the number of product units demanded, e.g., discount from 20th unit onwards. See "non-linear pricing."

List price

Catalog price, target price.

Logistics

Planning, control, optimization, and execution of flows of goods, information, and people; flows of goods, information, and people; flows of goods and people, etc.: transport, storage, handling, commissioning, sorting, packing, distribution.

Long tail spend

This expenditure area is not strategically managed; there is usually no contractual framework agreement for orders, mostly C-materials and C-articles.

M

Maintenance, Repair and Operations (MRO)

MRO (maintenance, repair, and operations) goods refer to "indirect needs" of production in an industrial company. In contrast to the production material, these commodities are not substantially included in the products. They are maintenance materials, spare parts, tools, operating supplies, office supplies, etc. The clever influencing of this special cost category still holds considerable potential in many companies (for example, through standardization).

Make or buy

A.k.a "Build or buy," this refers to the choice between making a product in-house or or buying it from an external company. Complex cost-benefit calculation for non-critical activities in terms of resources, capacity prices, time to market, service quality, for instance.

Master data management

Master data management; aims at continuous optimization of data quality and data exchange between employees or departments. Data must be enriched, described in a standardized way (uniform terms and information), formatted, stored, and retrieved across all company units to accelerate processes. In many companies, this is still not solved adequately.

Master service agreement

The framework agreement lists rights and obligations and other regulations, such as terms of delivery and payment that apply to all individual contracts also in the future.

Material requirements planning (MRP)

Determination of required materials according to type, quantity, quality, time; focus: efficient and effective supply (keep only as much as is needed in the short term) and as little waste as possible.

Maverick buying

Purchasing of internal demand carriers bypasses purchasing, employees purchase without authorization and (sometimes ignore) specifications; the goal is to minimize or eliminate this quota. Maverick buying is often expensive and inefficient. To prevent maverick buying, there are solutions that create transparency and clear assignments and approvals (products, prices, etc.).

Minimum order quantity (MOQ)

Order specification of the supplier in quantity or price (expressed in units per SKU). The MOQ of a supplier is sometimes based on MOQ conditions of their sub-suppliers: Especially in China, some suppliers rely on high MOQs because they often have lower profit margins.

N

Nearshoring

Relocation of operational work processes to nearby foreign countries. For instance, German, Austrian and Swiss companies, might nearshore for example, IT projects to Poland or Romania.

Negotiation

Topics of negotiation could include optimal pricing, volume variation, quality, delivery reliability, listing, values, win-win, investments, expectations, and constraints. A position in negotiations always depends on whether it is a buyer's or seller's market.

Net amount

An adjusted part of a larger whole (gross). Examples of a net amount are net weight (total weight of the goods without packaging) and net price (excluding applicable taxes).

Non-linear pricing

Quantity-based price differentiation. It means that the price per unit of a product does not vary proportionally with increased quantity. For an alternative approach, see "linear pricing."

O

Off-the-shelf

Clause "ex stock" means: The goods are sold as they are in stock. The buyer bears the packaging costs in the case of mail-order purchases. See also: Incoterms.

Onboarding (suppliers)

Connection or integration of suppliers into their own electronic or automated processes and systems for cross-interface (multi-level) exchange of data and information.

Open tendering

In this case, the contracting authority publicly invites an unlimited number of companies to submit tenders. Any interested company may submit a tender. The suitability is checked by evaluating the tenders, and the contract is awarded to the most economical tender.

Open-book contract

Buyers can gain insights into their suppliers' books and see their cost structure and calculations, which should strengthen their partnership. Example calculation: The supplier offers "company x" the items based on the respective net purchase prices ("base price") plus a fixed markup to cover all costs and the company's profit (= "open book markup"). For this purpose, the purchasing department is provided with a cost price list of the entire assortments available on the production launch date. In addition, purchasing and vendor agree on one or more markup rates (based on the supplier's contribution margin calculation). No further action is required if the markup rates correspond to the agreement. If there are deviations, a correction must be made as a reimbursement (period to be determined).

Operating cash flow

The balance between incoming and outgoing payments = cash flow. Liquid funds act as an indicator of the competitiveness of a company.

Operating expenses (OPEX)

Operational expenditure, including costs of raw materials, consumables, and supplies, personnel costs, and depreciation. OPEX is a part of the profit and loss account.

Operational level agreement

Intra-organizational, non-contractual agreement to secure a higher-value agreement with third parties.

Option

Refers to the right to buy or sell an agreed item at a later date at an agreed price; conditional forward transactions (derivatives).

Original equipment manufacturer (OEM)

An original equipment manufacturer (OEM) manufactures components or products but does not sell them to the retail market. Instead, an OEM delivers its original parts to its customers for further processing. However, there are exceptions, such as in the automotive industry, where manufacturers such as Daimler, BMW, and Tesla are referred to as OEMs.

Outsourcing

Transmission of company tasks and structures to external service providers requires complex cost-benefit analysis. Outsourcing enables a company to put its resources into its core tasks. See also "Make or buy."

Overspecified

Over-specification considers irrelevant (independent) variables that do not influence the dependent variable. The aim is to avoid unnecessary over-specification during development (e.g., software).

P

Payment terms

Regulation of the payment of monetary debts of payers in transactions. Longer payment terms enable working capital improvements.

P-card

Purchasing card or company debit card that buyers and other authorized persons use to order goods and services directly and independently from pre-defined suppliers. A third party acts as an authorization point for orders, e.g., Lufthansa AirPlus, VISA, Dresdner Bank.

Performance review (supplier)

Performance review; assessment of the performance of a supplier. Example: detailed check of the sustainability performance using online evaluation or an on-site audit.

Preferred supplier

Category for selected suppliers; for example, for every bid, they are asked about the material group and are allowed to participate in regular meetings even in the early product development phase. The purchasing department guarantees fixed acceptances. The vendor is committed to exclusivity. Both sides benefit from close co-operation.

Pre-qualification questionnaire (PQQ)

Must be completed by suppliers or contractors when they submit a tender for work or if they wish to be included in the list of approved suppliers of the purchasing department (application).

Prescriptive analytics

Prescriptive analytics can optimize purchasing decisions and supply chain operations by analyzing data to predict outcomes and suggest decision options.

Price on application (POA)

In procurement systems, certain functions can be used to submit online price requests to any supplier automatically.

Procurement process cycle

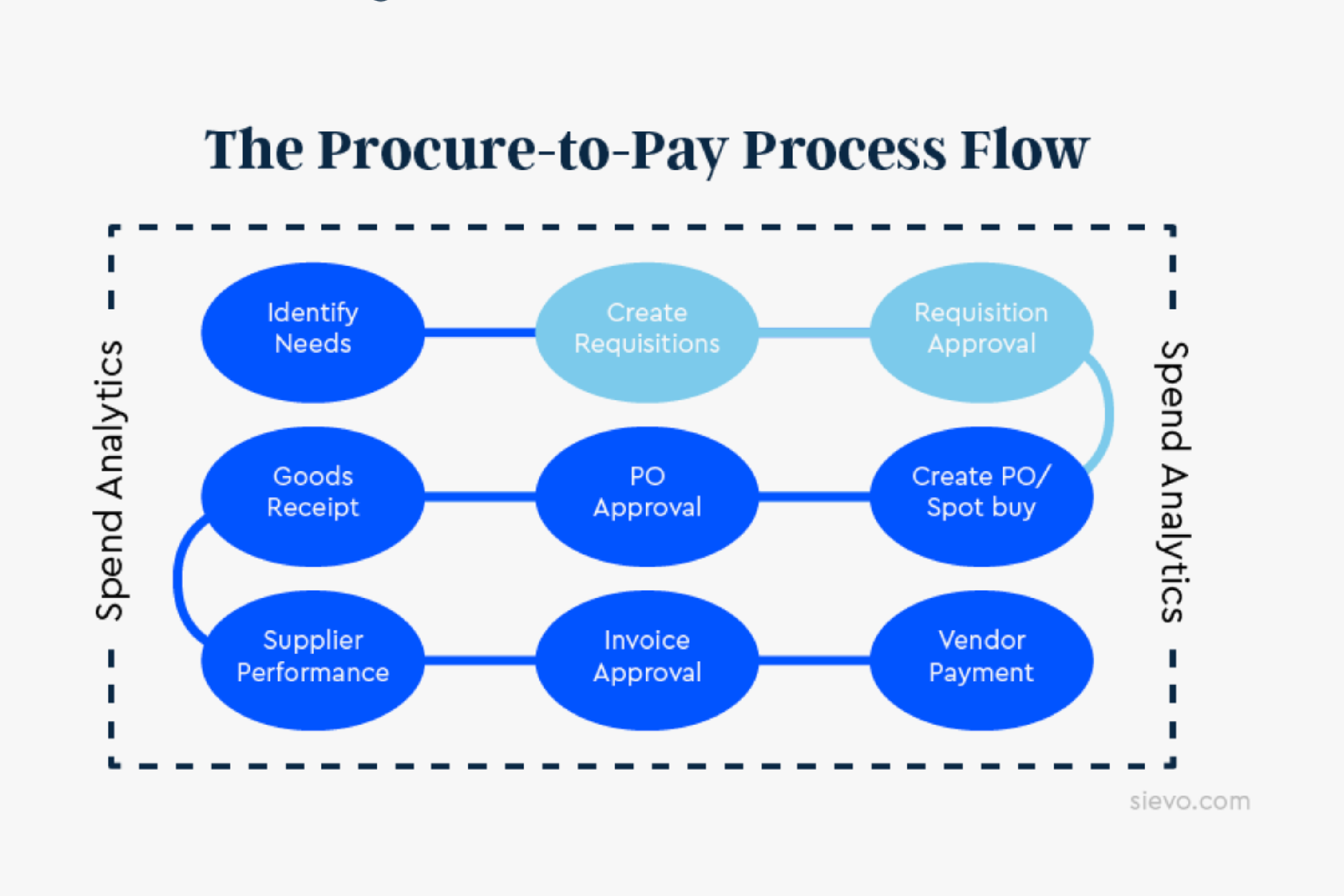

The procurement process cycle includes all steps for identifying and procuring new products or services, e.g. determination of requirements, identification of potential suppliers, comparison of alternatives, review and approval of payments. Variations of the procurement cycles include source-to-contract (S2C) and procure-to-pay (P2P) processes.

Procurement system

There are best-of-breed solutions or complex full-suite solutions that automate several process steps. See "best of breed" and "full-suite." Examples of application fields or tool categories: Plan-to-Strategy, Source-to-Contract, Requisition-to-Pay (R2P) or Procure-to-Pay2, Category-specific tools, Supplier Management (SRM), Quality Management, Spend Analysis/Controlling.

Procurement transformation

Strategic reorientation of purchasing; restructuring of the process and organizational structure of purchasing (from vicarious agent to strategic business partner). In transformation, measures should be accompanied by change management.

Procurement value levers

The cost levers of purchasing are manifold - they are all aimed at influencing a company's spend or reducing total costs. In Kearney's "Purchasing Chessboard" there are 16 different levers (and 64 methods) listed, including innovation breakthrough, value chain management, cost partnership, risk management, volume bundling and target pricing.

Procure-to-invoice (P2I)

Procure-to-invoice (P2I) is a sub-area of the procure-to-pay process - with purchase requisition, order confirmation, entry of goods receipt, invoice entry, invoice verification and release.

Procure-to-pay (P2P)

Procure-to-pay (P2P) is a set of processes used in larger organizations to request and pay for goods or services. P2P integrates procurement operations with financial processes, such as accounts payable to ensure costs are controlled and aligned with accounting reporting practices. See also "procure-to-invoice".

Proof of concept

The principle feasibility of a project should be demonstrated in the appendix to an initial project by testing the idea in a smaller scale. Building on the experiences from a proof of concept, a decision is made on the further progress of the project.

Proposal

A procurement system automatically generates proposals (also alternatives) for products, goods or materials "requested" in the system. Example: A procurement proposal is created for vendor X for 5,000 pieces because vendor X has not entered a maximum lot size.

Public procurement

Public institutions such as municipalities and ministries acquire good or services in a contractually regulated manner from companies that they have selected. For example, when building public a school, buying furniture for a ministry.

Purchase invoice

Incoming invoice, also request for payment. Mandatory details (§ 14 Paragraph 4 UStG):

complete name and address of the entrepreneur providing the service and of the recipient of the service, tax number or value added tax identification number (VAT ID number) of the entrepreneur providing the service, date of issue, invoice number (consecutive, one-off, series of numbers), quantity and type (customary commercial designation) of the delivered items or the scope and type of other services, time of performance, in the case of advance payments/down payments, remuneration for the delivery or service, reduction in remuneration agreed in advance (e.g., discount), applicable tax rate, reference to tax exemption.

Purchase order

A purchase order (PO) is an official document created by an internal customer or buyer, that authorizes a purchase transaction for goods or services from a supplier. POs play an important role in spend control. An automated PO process helps speed up the process, improves communication, and minimizes financial risks.

Purchase price variance (PPV)

Difference between the cost of the order and the standard cost of the item.

Purchase requisition

A purchase requisition is handed to the purchasing team to procure a certain quantity of a material or service on a certain date. A purchase requisition results from a requirement for goods or services.

Purchase-to-pay cycle (P2P)

Includes all steps in the process from the purchase to paying of goods automatically via tools, EDI, tracking and e-invoicing software

Purchasing

Purchasing includes all the operational activities of the purchasing department, e.g. determination of requirements, writing of orders, obtaining quotations, commissioning, monitoring delivery dates.

Q

Qualified bid

Qualified bid or offer as a part which is necessary to conclude a contract. A declaration of intent which must be received in order to conclude a contract under the law of obligations. The offer specifies (demanded) goods, number of goods, price of the goods, discount, place of performance, delivery time and terms of payment.

Quality control

Systematic monitoring of all factors influencing the product quality and production process. It is necessary to define one's own quality standards and to agree with the suppliers or service providers on the degree of fulfillment in terms of processes, materials used, service. Quality control is usually carried out in spot checks.

Quote

Quota = (percentage) share of a total quantity or number; refers to stock sizes (size at a certain point in time). Examples: purchasing quota, complaint quota.

R

Rebate

Discount, deduction from an amount that is paid.

Receipt of goods

Acceptance of goods. Includes all activities from receipt of the goods via inspection to storage.

Request for proposal (RFP)

Invitation to tender. Request, e.g. for a system or project offer with specific itemized factors. By issuing an RFP it is possible to map out potential vendors for a project and compare how they would suit the buyer's needs and requirements.

Request for quotation (RFQ)

Request for detailed information on prices and conditions based on a concrete specification. A detailed description of all parameters of the planned procurement.

Requisition

Purchase requisition is a request to buy a certain quantity of a material or service on a certain date.

Residual value

Value of an asset at the end of its useful life.

Reverse auction

Bidders underbid each other and the lowest bidder is awarded the contract in an auction.

RFx

Electronic inquiry. The X is a placeholder for concrete offers for goods, products, services and information. Buyers use an eRfX tool to request conditions for their requirements from various suppliers in a structured manner. This makes a comparison possible. See "request for proposal" and "request for quotation" for reference.

S

Sales and operations planning (S&OP)

Monthly process for interdepartmental corporate management. Also for integrated planning, control and monitoring of the supply chain.

Samples

A manufacturer or a supplier delivers or produces a sample before an order is placed (sample procurement).

Savings tracking

Monitoring of savings. There are tools that help in managing purchasing initiatives and analyzing savings in real-time. The goal of savings tracking is to provide accurate evidence and actionable insights for the decision-makers.

Schedule of rates

List of tariffs, list of rates, the scale of charges, price list.

Sealed offer

In a sealed-bid auction, two or more bidders submit a non-transparent bid (virtually in a "closed envelope").

Service level agreement (SLA)

Agreement or contract between the customer and the service provider; definition of the mandatory standards to be met.

Should cost model

Target cost model. Cost specifications (planned costs) are adjusted to the actual capacity utilization.

Single source

Purchasing from a single source, i.e. a single supplier. Targeted, deliberate restriction that requires trust and close cooperation.

Small and medium-sized enterprises (SMEs)

Micro, small and medium-sized enterprises (SMEs) are defined in EU Recommendation 2003/361. According to this recommendation, an enterprise is classified as an SME if it has no more than 249 employees and an annual turnover not exceeding €50 million or a balance sheet total not exceeding €43 million.

Source-to-pay (S2P)

Source-to-pay is the end-to-end process from supplier search to payment for goods or services delivered. Steps include sourcing, negotiation, contracting, invoicing, approval, fulfillment and finally payment.

Source-to-contract (S2c)

Source-to-contract is the set of strategic processes used to identify and select a strategic vendor for products or services. S2C may include past spend analysis, supplier performance evaluation, development of sourcing strategies, requests for proposals (RFX), auctions and negotiations.

Specifications

Precise determination of the potential customer's requirements for the characteristics of a product, service, performance or system.

Spend analysis

Spend analysis is the active review of procurement spend to decrease costs, increase efficiency or improve supplier relationships. In procurement, spend analytics refers to the systematic collection, cleansing, classification and analysis of spend information either with dedicated software or through spend cube projects.

Spend cube

Output cubes, method for structuring for the following questions: What is being bought? (product group) Where did costs arise? (cost center) From whom is the purchase made? (suppliers). Steps of making a spend cube are data collection, data consolidation and conversion, classification of suppliers and expenditures and final evaluation of the data, and construction of customized reports.

Spend leakage

Spend outside the suppliers that are not on the list of pre-approved suppliers.

Spend management

Spend Management is intended to increase the leverage effect of the procurement of materials, products and services. It aims to make all sources of spend transparent, to identify optimization potentials and to recognize risks in the supply chain at an early stage. Realized savings increase profits and can also benefit investments.

Statement of work

Description of the services to be provided during the contract period (project period), such as quantities, services, results.

Stock

The amount of goods in the warehouse stock.

Stock keeping unit (SKU)

Storage unit; a product is assigned an individual registration number for identification and tracking.

Strategic sourcing

Strategic sourcing is the process to continuously assess and improve the value created from procurement activities to a business or an organization. While tactical sourcing is understood as the acquisition of goods or services at the lowest cost, strategic sourcing takes into consideration a broader view balancing factors like competitive market conditions, negotiating power, developing supplier relationships and mitigating supply risk.

Subcontractor

The subcontractor or sub-supplier is the supplier to the contractor. The number of (usually unknown) sub-suppliers can be many along the supply chain. Consequences of having many subcontractors may include non-transparency, quality issues, and other risks.

Supplier

A person or an organization that provides their products or services against a payment.

Supplier consolidation

Reducing the number of vendors for purchasable items to streamline operations and negotiate better terms, as well as improving your supply chain visibility.

Supplier management

Supplier management comprises all systematic activities related to the evaluation, selection, development, and strategic integration of suppliers at different levels of the value chain. Together with suitable suppliers, supplier management aims to eliminate weak points as far as possible, identify potentials, and optimize quality, delivery times, and costs—thus developing the relationship as a whole. One of the success factors in supplier management is supplier performance management (data-driven approach), which aims to ensure that suppliers deliver precisely what was determined in the contract.

Supplier risk management

Supplier risk management comprises the holistic process of managing risks along the supply chain: from risk identification and assessment to controlling measures for risk minimization.

Supply base reduction (SBR)

Process of reducing the number of active suppliers, and making purchasing more efficient.

Supply chain decarbonization

Process of reducing carbon emissions within the supply chain with strategies such as improving energy efficiency, switching to renewable energy sources, and enhancing logistics to lower the carbon footprint.

Supply chain resilience

The ability to withstand and recover from disruptions. This includes anticipating potential threats, preparing and responding effectively to disruptions, and restoring normal operations as quickly as possible.

Sustainable procurement

Sustainable procurement is an important part of an organization's sustainability management. This is the process of purchasing products and services that have a lower environmental impact than comparable products and services.

T

Tail spend

Long-tail spend in procurement refers to the large quantity of low-value items that are not actively managed as strategic categories of costs. The Pareto principle can be applied to tail spend management, where often 80% of suppliers account for just 20% of spend in what is known commonly as the "80/20 rule."

Tariff

Customs, fees.

Taxonomy

Classification, for example, classification of suppliers into different categories.

Tender management

Organization of tenders and auctions.

Terms of reference

Shows the task of defining, developing, and verifying a specific object or project.

Third-party logistics (3PL)

External business partners that take over, for example, transport and storage for their customers.

Total cost of ownership (TCO)

Costs over the complete life cycle of a product: purchasing and operating costs as well as possible disposal costs.

Total quality management (TQM)

Comprehensive quality management, in which all employees are involved. TQM includes customer orientation, leadership, employees, improvement, and relationship management, with process-oriented approaches for fact-based decision-making. Valid standard: ISO 9001:2015-09.

Transaction costs

For example, costs for initiation, information procurement, adaptation, processing, and control.

Transparency

Often a goal in procurement is to have transparency to data, quotas, consumption, spend, supplier base (various tiers), risks, among other things. Transparency can be enhanced by using various tools.

U

UNSPSC

Abbreviation for United Nations Standard Products and Services Code. International taxonomy system of merchandise management for the cross-company classification of goods and services of all kinds (especially in the Americas).

V

Vendor management

One of the core tasks of purchasing: the professional strategic design of relationships and control mechanisms for better services, prices, quality, etc. See "supplier management."

Vendor portal

System or central platform for the maintenance of supplier master data and the handling of business processes between purchasing companies and suppliers.

Vendor rating

Supplier evaluation; systematic evaluation of the supplier or his performance on the basis of defined standard features, e.g., point evaluation (scoring model), profile analysis, and price structure analysis.

Volatile spend

Fluctuating expenditures. For example, raw materials and energy have fluctuating (volatile) costs.

W

Waiting time charge

The agreed fee for an unplanned waiting time, e.g., a truck waiting at the ramp to be loaded.

Warranty

A voluntary commitment of the manufacturer or (rarely) the dealer that goes beyond the sales contract.

Working capital

Working capital (also: current assets) are assets subject to a current turnover, e.g. raw materials and supplies, semi-finished and finished products, advance payments, receivables, bank balances.

Procurement Glossary

English

Spend Analysis Beyond Dashboards

Access our new and improved playbook for Spend Analysis in the era of AI: go beyond dashboards to unlock the fullest potential of procurement spend data.

Playbook: Spend Analysis Beyond Dashboards

Access our new and improved playbook for Spend Analysis in the era of AI