A purchase order (PO) is an official document, created by the buyer, which authorizes a purchase transaction for goods or services from a supplier.

A purchase order is more than just paperwork. It plays an important role in controlling business purchases. A well-structured PO process:

Let’s dive in.

Why Do Companies Use Purchase Orders?

Businesses of all sizes can benefit from more financial control. Purchase orders are one way to keep control of costs.

Here are five key benefits of purchase orders to businesses:

- Clearly define business needs and supplier expectations

- Create a standardized process that can be tracked and measured

- Improve budgeting and cash flow forecasting

- Serve as legally binding agreements when accepted by the supplier

- Support auditing and compliance through documentation

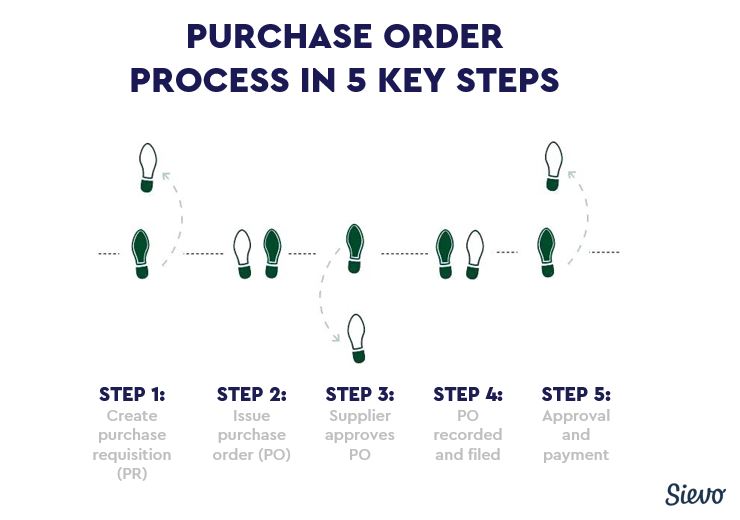

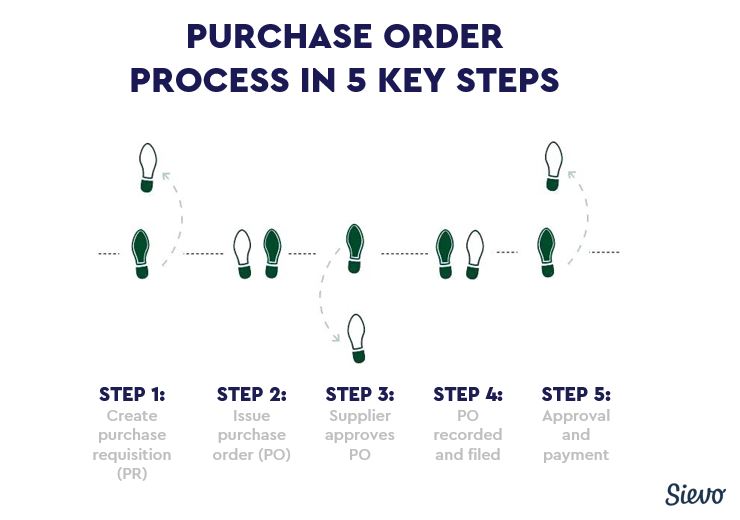

The PO Process Step-by-Step

The PO process fits into a larger procure-to-pay (P2P) process. It starts with identifying the business need, then continues through payment and auditing.

A well-managed purchasing system helps enforce agreed-upon price terms and ensures legal compliance.

Having a structured approach reduces errors and improves operational efficiency.

1. Creating a Purchase Requisition (PR)

The process starts with a team member submitting a purchase requisition, a formal request for the goods or services they need.

This document initiates the process and ensures internal alignment. It could be amended or added to before approval is received, or even canceled.

2. Issuing the PO

Once the PR is approved, a purchase order is created. It includes all key terms: pricing, delivery, quantity, and conditions.

Each purchase order includes a unique purchase order number that helps track and manage incoming orders accurately.

Electronic POs (e-POs) are increasingly common as businesses adopt automation to improve speed and reliability.

For large purchases, organizations usually issue a Request for Proposal (RFP) to their preferred suppliers.

Before the order can be issued, some level of financial authority is required to sign off the purchase.

Once approved, the PO is sent to the chosen supplier, usually via email or through a procurement system.

A PO typically includes:

-

Buyer and supplier info

-

PO number and date

-

Product or service description

-

Quantity, price, and payment terms

3. Supplier Approval

If any details are incorrect or unacceptable, the supplier may request amendments. If necessary, the supplier then approves the amended PO, usually via email or an e-procurement platform.

This approval marks a formal agreement and clears the path for fulfillment.

4. Delivery and Review

After the product has been delivered or the service has been performed, the organization will review the purchase to see if it meets acceptable standards.

For physical goods, the delivery is documented using a Goods Received Note (GRN). Services are typically signed off in a similar way.

This step ensures accountability and confirms that the supplier met their obligations.

5. Invoice Approval and Payment

On receipt of the invoice, it is matched to the PO. Provided all is correct, the invoice is paid as per the agreed payment terms.

Matching invoices to POs helps reduce errors, disputes, and duplicate payments.

Once the transaction is fully settled, procurement teams typically close the PO in their purchasing system to prevent further activity. This is a key part of clean recordkeeping.

Best Practices for Managing Purchase Orders

There are some best practices in day-to-day or transactional purchasing:

- Ensure that all employees involved in the purchasing process understand the policy, procedures, and approval methods that need to be adhered to.

- Establish an up-to-date panel of preferred suppliers that can provide quality products at acceptable prices and deliver reliable services. This provides the opportunity to compare prices and terms of supply with the minimum delay.

- Regular key suppliers of the same product or service can be engaged under a Master Agreement that defines pricing, escalations, and terms and conditions. Ensure that all product information is current and that complete catalogs are kept. This reduces interactions and eliminates excess paperwork.

- Maintain good relationships with current reliable suppliers so that problems can be solved quickly. Adversarial relationships are counter-productive and create unnecessary stress and cost.

- Where possible, purchasing information should be centralized and made accessible to all users. Use the best technology you can afford to streamline the PO process.

Common Pitfalls to Watch For

Even a solid process can run into problems. Look out for these common issues:

- Inflexible Suppliers: Suppliers may not offer discounts or cover delivery costs unless you ask. Always negotiate where possible.

- Errors on orders: Errors can be managed if addressed quickly with a supplier. Wrong quantities or sizes or delivery dates can be adjusted and the PO amended accordingly before any activities occur.

- Unauthorized POs: Pursuing purchases without the proper approvals can lead to budget overspending and compliance issues.

Many purchasing issues are the result of unclear communication or skipped steps. The good news? Most can be resolved quickly when you have the right systems and relationships in place.

Make sure your procurement tools allow you to:

- Track purchase orders easily

- Log all activity for auditing

- Close up POs promptly when completed

Photo credit: Robert McGoldrick - Flick