Understanding your suppliers—and your suppliers' suppliers—is essential for building a resilient, sustainable supply chain.

Without this visibility, organizations face increased risks including delays, quality issues, supply chain disruptions, and compliance failures.

Supplier tiering, or categorizing suppliers based on their relationships within your supply chain, is a proven framework for effectively managing these risks.

This guide explains what supplier tiers mean, why visibility matters, and how procurement teams can improve transparency across all tiers.

What Are Tier 1, Tier 2, and Tier 3 Suppliers?

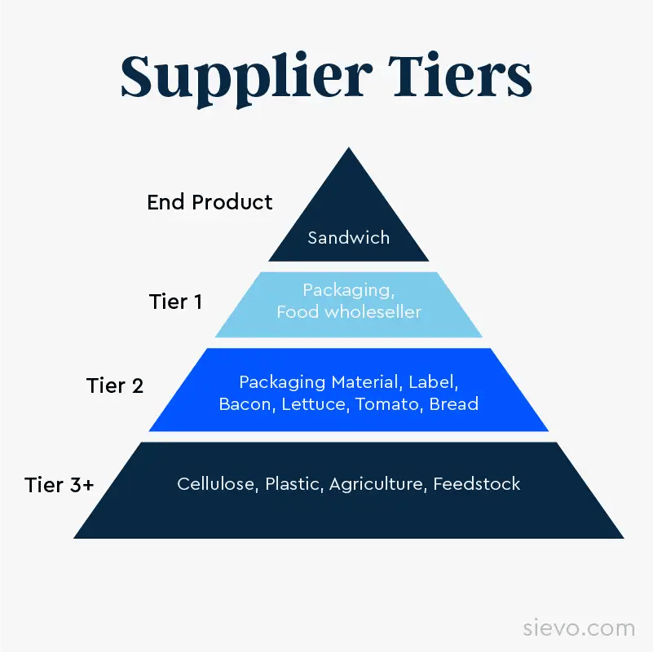

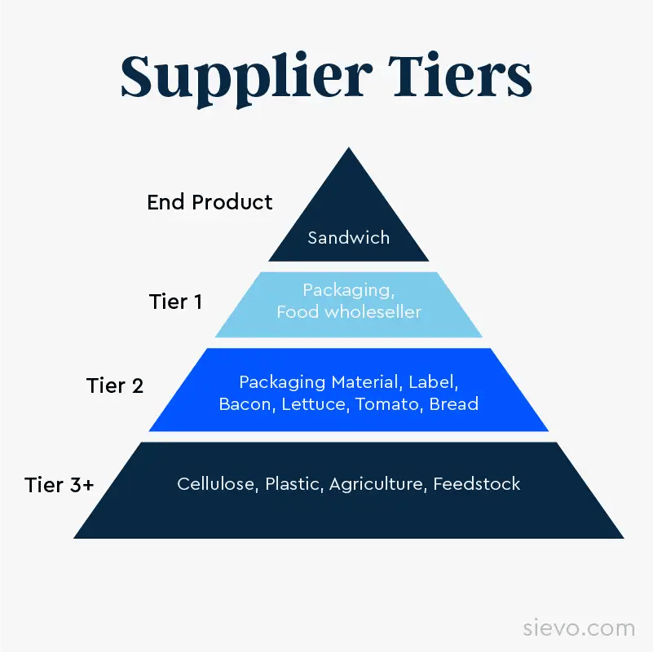

Suppliers can be broken down into three tiers:

Supplier tiering means organizing suppliers into tiers based on their importance and relation to your supply chain.

The concept of supplier tiering started in the automotive industry to identify how far away elements of the supply chain are from the production of the final product.

Why Is Supply Chain Tier Visibility Important?

Visibility into your supplier tiers is critical because risks often materialize deep in the supply chain, where they may not be immediately apparent to your organization.

Supply risk areas include:

- Operational risks, such as delays, shortages, and quality control issues.

- Governance risks, such as lack of compliance with laws and regulations

- Environmental risks, such as CO2 emissions and waste

- Social risks, such as human trafficking, child labor, poor working conditions, and low pay

- Cybersecurity risks, such as confidentiality breaches

Collaborative business models help mitigate risk and increase proactivity. Relationships with suppliers promote innovation and ensure continuity of supply.

How Much Visibility Do Organizations Actually Have?

A Deloitte CPO survey found that only 15% of CPOs have visibility beyond their tier-one suppliers. Achieving Tier 1 visibility is hard enough.

Why Is Tier 2 and 3 Visibility So Difficult?

Most buying organizations face significant barriers to deeper supply chain visibility:

-

Data fragmentation: Supplier information is spread across multiple systems, locations, and departments

-

Data decay: Supplier data is time-sensitive and quickly becomes outdated

-

Lack of direct relationships: No contractual leverage with sub-tier suppliers

-

Supplier reluctance: Partners may resist sharing proprietary information

Your Tier 1 supplier may be sourcing materials from a sanctioned country. Their subcontractor may not comply with your supplier code of conduct.

Relying solely on Tier 1 suppliers to provide compliance evidence is inadequate when you're managing hundreds of category suppliers.

How to Improve Supplier Tier Visibility?

There are essentially 3 proven strategies to get visibility on all your suppliers.

Strategy 1: Map Your Supplier Network

Start by mapping your Tier 1 suppliers and segmenting them by their business criticality. You need to start somewhere!

Action steps:

-

Identify your most strategic Tier 1 suppliers

-

Create a complete picture of the tiers for each key supplier

-

Use this mapping to improve risk management and identify improvement opportunities

Strategy 2: Establish Traceability Systems

Track the origin of products and materials throughout your supply chain. Effective traceability enables you to truly understand what your end products are made of and helps secure compliance with key requirements.

Benefits of traceability:

-

Verify material origins and sourcing practices

-

Document compliance with regulations and standards

-

Respond quickly to quality issues or recalls

Strategy 3: Foster Open Communication and Trust

Build transparent relationships at all supplier levels. Establish both formal governance structures and informal communication channels.

Addressing supplier concerns:

Suppliers may resist sharing data for legitimate reasons:

Building trust:

-

Use NDAs and non-competition clauses to provide assurance

-

Emphasize that modern business relationships are built on transparency

-

Demonstrate that collaboration benefits all parties in the supply chain

The Role of Data and Technology in Supplier Visibility

Visibility becomes increasingly difficult as you move deeper into the supply tiers. Manual tracking is simply not feasible at scale. Data collection and analysis should be automated.

Essential Supplier KPIs may include supplier inventory, lead times, quality, delivery performance, sustainability performance, and diversity. Difficulties in maintaining service levels may reveal a problem further down the chain.

Technology Solutions for Multi-Tier Visibility

Software platforms are making it easier for organizations to map Tier 2 and Tier 3 suppliers and track performance across all tiers.

Key capabilities to look for:

-

Automated supplier discovery and mapping

-

Real-time risk monitoring and alerts

-

Integration with existing procurement systems

-

Compliance tracking and documentation

Real-time visibility enables faster response when serious problems occur, turning potential crises into manageable situations.

Aligning Procurement Analytics with Real-time Supply Chain Risk Monitoring - Webinar with riskmethods