In the procurement world, offshoring is the relocation of production, business process or operations from one location to another, usually to less-developed countries, to reduce costs.

The main reasons for offshoring are improved production efficiency, improved turnaround, the advantage of lower labor costs, looser environmental and employment regulations, and better availability of raw materials.

The time zone difference also plays a significant role in service availability around the clock. Major companies have benefitted from offshoring over the past decades, but the landscape is changing.

In this article, we'll cover different outsourcing models and how they can support your sustainable procurement strategy.

Post-pandemic supply chain risks

Post-pandemic years will be challenging for procurement. According to Hackett's CPO Key Issues Study, key business risks include increased supply chain disruption, inflation, commodity volatility, and labor and skills challenges.

CPOs reported that resilience is their number one priority over the need to deliver cost savings in an inflationary environment. Managing ongoing supply disruption and its impact on revenue is procurement’s top risk area.

Some challenges resulting from the Covid-19 pandemic are still with us, such as the slow recovery of supply. Geopolitical crisis adds its own spice to the dynamic procurement environment. Procurement will play a key role in addressing versatile risks and in developing mitigation strategies.

"Continued uncertainty, new risks and digital disruption shape the 2022 procurement agenda" - Hackett Group, 2022

Hackett reports that the procurement executives surveyed are reasonably confident in their ability to achieve supply risk objectives. They point out that improving analytical, modeling, and reporting capabilities; aligning skills and talent with changing business needs, and improving procurement agility are closely linked to their ability to manage risks.

The outsourcing strategy is changing – from offshoring to onshoring

There is a visible shift away from sourcing manufactured goods and specialty items from low-cost countries towards locations closer to home, reducing uncertainty, delays, and supply disruptions.

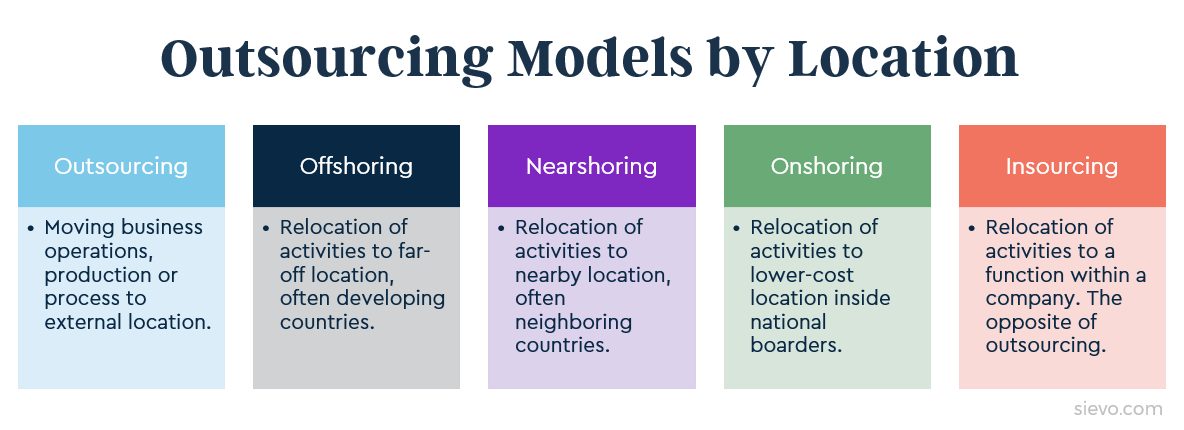

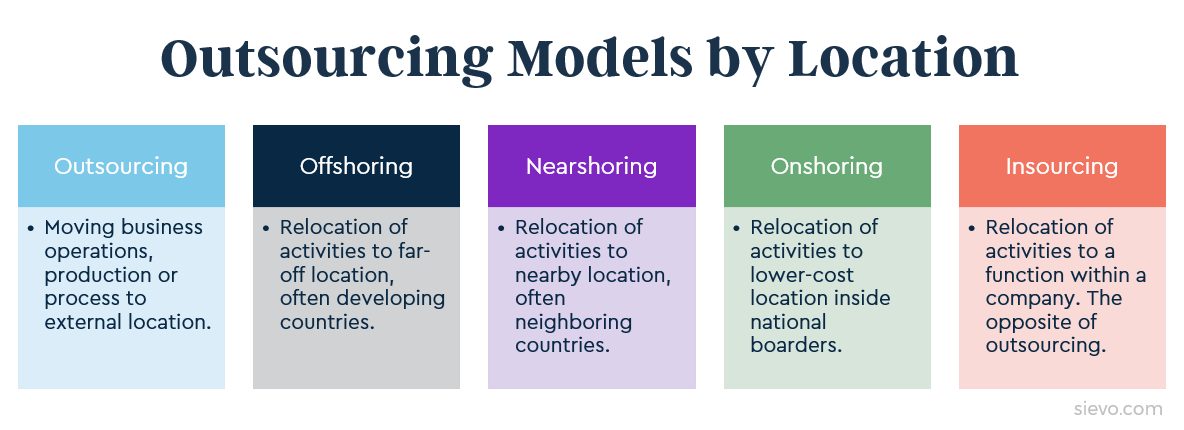

The image below describes different sourcing models by their geographic location:

Nearshoring is outsourcing from a relatively close location. Nearshoring means outsourcing a business process or part of it from a nearby country, preferably a neighboring one or one on the same continent. There are often cultural and language benefits as well as faster logistics, communications and fewer misunderstandings.

Onshoring is domestic outsourcing. Onshoring refers to outsourcing business process or part of it from another location inside the national borders.

Here's an example of sourcing models:

- If a German company sources from the Philippines, that’s offshoring.

- If a German company sources from Poland, that’s nearshoring.

- If a company from Berlin sources from Bielefeld, that’s onshoring.

Sustainable benefits of onshoring

Onshoring of products and services is becoming one of the corporate responsibility objectives for organizations. Onshoring is linked to sustainability, diversity, and local sourcing goals.

Business processes and manufacturing are sourced closer to home to support the local economy and businesses. Shared infrastructure, tools, and facilities are used to promote efficiency as well as better coordination and communication. Data security and control are also improved.

Benefits of Nearshoring/Onshoring include:

- Reduced time-to-market

- Greater speed and agility in delivery and distribution

- Improved visibility, oversight and control of processes

- Reduced errors caused by cultural and language barriers

- Improved and more efficient communication in same time zone

- Lower transport costs, customs and duty charges

- Lower buffer stock and emergency order costs

Onshoring of production

The recent delays due to port congestion and container shortages make the decision to source goods closer to markets easier. Sourcing regionally or locally saves time that can translate to guaranteed delivery dates.

Labor costs for product manufacture and distribution may be higher but the difference may be offset by no or little airfreight required and lower inventory levels. Another reason to bring vendors closer can be found in the change in consumer behavior: the need for speed of delivery, concerns about carbon miles, and exploitation of labor.

Supporting domestic or nearby labor, paying fair prices to workers, and reducing the transportation distance of the product can be seen as acts of corporate social responsibility in the eyes of consumers.

The product may cost a little more but peace of mind for the customer provides a competitive advantage. Improved cultural fit and communication can be seen in the compliance with product specifications and standards for quality.

Onshoring of services

Offshoring of services to low-cost countries such as India, the Philippines, and Malaysia is well established; these countries have been able to provide skilled technical services, especially in IT.

There is a large talent pool where the pricing is very competitive compared to western countries. Because of differing time zones, service can be delivered 24/7.

However, the geographic and cultural gap can sometimes cause more trouble than expected. For example, language barriers often require more focus on management and service quality.

Nearshoring/ onshoring services can improve communications and reduce the need for close oversight of projects. Some customers may have requirements for data security and control that require the service processes to be delivered within the same region.

Developing supply chain resilience and sustainability

Changes in legislation and consumer demand as well as new emerging risks create a need to adjust supply chains.

The trend towards nearshoring and onshoring is likely to grow as freight costs continue to rise. Bringing vendors closer to customers means that companies can react more quickly to market fluctuations and changes in demand. Buying regionally and locally promotes corporate sustainability goals and reduces the carbon footprint of products.

Achieving the balance between offshoring/nearshoring/onshoring requires supply chain visibility. Procurement teams that can manage to find the right combination of vendors and sources are in a great position to make their supply chain more sustainable and resilient.

To do this, they need the tools to identify sourcing opportunities, consolidate suppliers and make decisions that can help mitigate risk. The ability to assess delivery performance and total cost of ownership is a must for effective sourcing decisions. Real-time insights based on reliable data can identify potential internal and external challenges.

Header photo by Monica Suarez.