Centralized procurement means that purchasing is managed at the headquarters level. Decentralized procurement means that purchasing happens in various business units and locations.

CPOs must constantly re-evaluate their structure and priorities to ensure alignment with stakeholders, especially when embarking on any transformation project.

As procurement organizations mature, leaders will revisit their operating model to establish how well it works.

Centralized vs decentralized purchasing

There are advantages and disadvantages to both centralized and decentralized procurement structures.

Most modern procurement organizations have adopted a hybrid model, somewhere between fully centralized and fully decentralized. This is often referred to as “center-led.”

Company size, industry, location, growth rate, and categories under management are all factors that affect whether a more centralized or more decentralized structure is better.

In industries where products are similar throughout the world, such as oil and gas and automotive, structures tend to be more centralized.

Some sourcing categories such as raw materials, MRO items, and basic IT equipment are more suited to centralizing. Other indirect categories such as transport logistics, marketing, and professional services may not.

See how Spend Analytics software can be adapted to your organization--Read the guide Spend Analysis 101.

What is centralized procurement?

When procurement is fully centralized, all purchasing decisions are made through a single, dedicated organization, either at company headquarters or at some designated regional or divisional level. The authority to make purchasing decisions is centralized

Advantages of centralized procurement:

- Better management of spend, that leads into benefits of scale

- Implementation of holistic category strategies and tactics

- Improved compliance and standardized processes

- Specialized, dedicated team for purchasing

- Centralized management of data and information

- Improved risk mitigation

- Centralized management of environmental, sustainability and governance agenda

- Better relationship management and one point of contact for key suppliers

Disadvantages of centralized procurement:

- Inefficiency as operation may grow too big or complex to run

- Misunderstanding of local requirements

- Delays in the delivery of goods and services to end-users

- Maverick buying outside of contracts will occur

What is decentralized procurement?

Where procurement is fully decentralized, each business unit, functional or geographic unit is responsible for its own purchases. This means that procurement activities are spread over many countries and locations.

For large, global companies decentralization is generally a matter of practicality, Spend Matters argue. If a company has locations all over the globe, it may not be realistic to direct all purchases through single office.

Although some of the advantages of a central model are lost, supplier diversity and the development of small and medium enterprises (SMEs) are better enabled.

Purchasing decisions can be made more quickly to benefit from seasonal discounting and to avoid stock-outs. Maintaining interpersonal relationships on local level is more cost effective.

Decentralized structures may suffer from poor adherence to corporate policy and processes and teams are unable to share best practices with other business units.

There are challenges related to the performance of key global suppliers, causing uneven success. Overall operating costs of procurement are likely to be higher than with a centralized model.

Advantages of decentralized procurement:

- Supplier diversity and use of local alternatives

- Interpersonal relationships and supplier knowledge

- Faster decision-making

- Short delivery time

- Specialization and local requirements

Disadvantages of decentralized procurement:

- Suboptimal management of spend

- Missing out on benefits of scale

- Scattered category strategy execution

- Scattered management of information and data

- Duplication of effort in vendor and contract management

- Non-compliances with corporate policy and processes

- Risk mitigation is not always fully supported

The center-led procurement model

Center-led procurement model applies a category management structure that supports the rollout of sourcing strategies and contracts to the functional and regional levels. Center-led model is often called a hybrid model.

The centralized and decentralized models both have their strengths, the key to optimizing procurement comes from leveraging the benefits of both.

A center-led structure has a core procurement team focused on setting up the policies, processes, infrastructure, best practices, and knowledge sharing. This model is prevalent in most large organizations with global operations.

The best procurement organizations concentrate on defining strategy and policy as well as applying best practices to both direct and indirect procurement. Category management strategies can be designed to adapt to individual country requirements, and local regulations and to manage existing global or regional contracts. In-country teams can be empowered to manage tactical purchasing activities locally.

Stakeholder challenges in centralized and decentralized procurement

Is not easy to satisfy all stakeholders and end-users, whatever the model. The best solution seems to deliver results through open lines of two-way communication and processes that are flexible enough to account for regional and cultural differences.

One way to generate higher levels of stakeholder support is to ensure that the global category management structure is replicated in decentralized business units or regions, probably on a more limited scale. It has been suggested that this type of structure encourages agility and innovation as well as better compliance with contracts.

Procurement organization models are in change

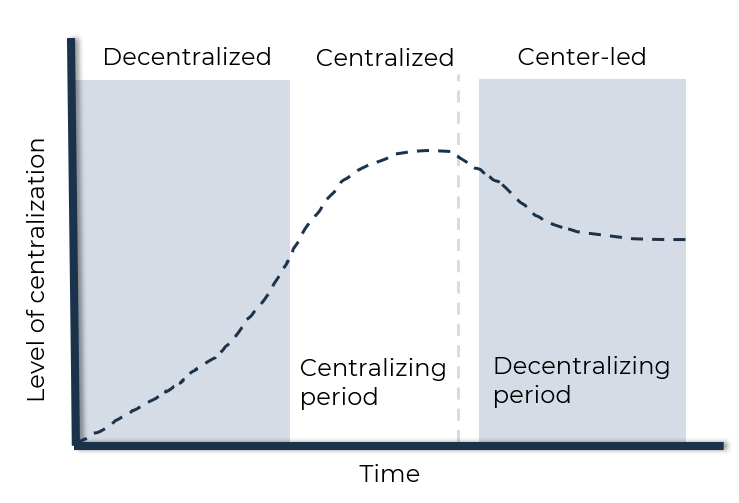

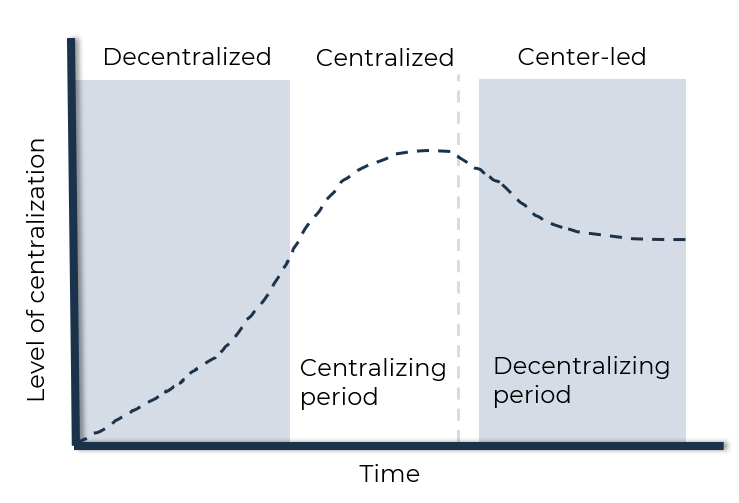

How does an organization decide on a structure? Often the phases of development follow the curve presented below. As procurement organizations mature, they tend to prefer a centralized operating model, and an era of centralizing takes place. No single model can sustain the expected benefits indefinitely.

Savings delivered from a given procurement operating model erode over time and become more and more difficult to achieve. Organizations may grow too complex to manage centrally or business model may require more localized approaches in sourcing and supplier selection. The model just gets tired.

Often a structural change may be needed to allow procurement to deliver value in new ways, enabling benefits to be sustained or even improved. Procurement must be aligned with wider strategic objectives and the culture of the organization to continue to deliver value.

Hence, a center-led approach may be the preferred end result of the development curve, allowing more flexibility yet securing governance and appropriate risk management.

According to KPMG research, some companies are seeking to forge more center-led structures. Procurement organization models are in a period of rapid change and most organizations follow the same path, they report.

On the other hand, some are refining their pre-existing structures to adjust to the changing economic environment. The operating model may vary between procurement categories as one size does not fit all.

Category-specific projects lead the transition phase, as organizations seek to right-size their strategies and match their categories to the market.

Header photo by: Steve Johnson (unsplash)