Materials forecasting involves creating direct materials cost budgets and forecasts to help your business better understand and manage its future profitability.

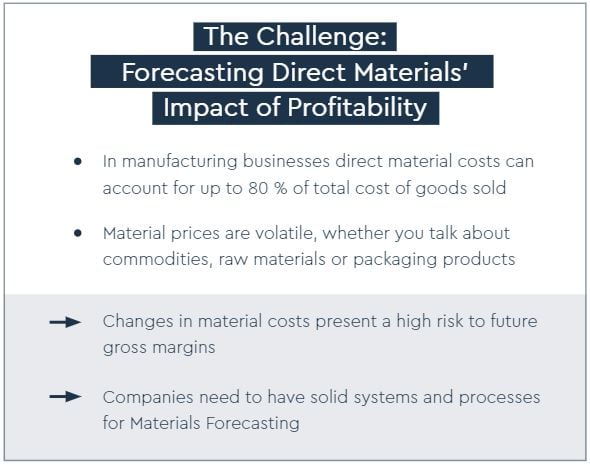

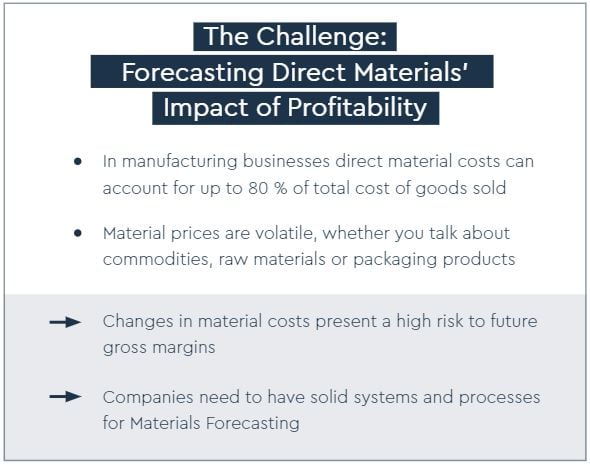

In manufacturing businesses, direct material purchases are the largest cost driver, and it is mandatory to understand how expected material price developments will affect your gross margins. However, building a robust materials forecasting system is far from easy.

Whether you are looking to build materials forecasting capabilities from scratch or want to step up the game with your existing processes, we got you covered.

This blog discusses what materials forecasting means in large enterprises – its value and benefits, but also the main challenges and solutions to those.

Understand and Manage your Future Profitability

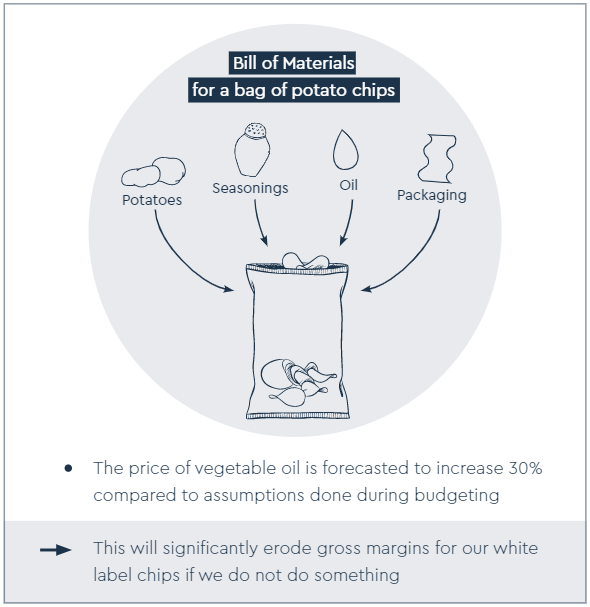

Materials Forecasting is a key tool for understanding and managing how direct material costs affect a company’s future gross margins and profitability.

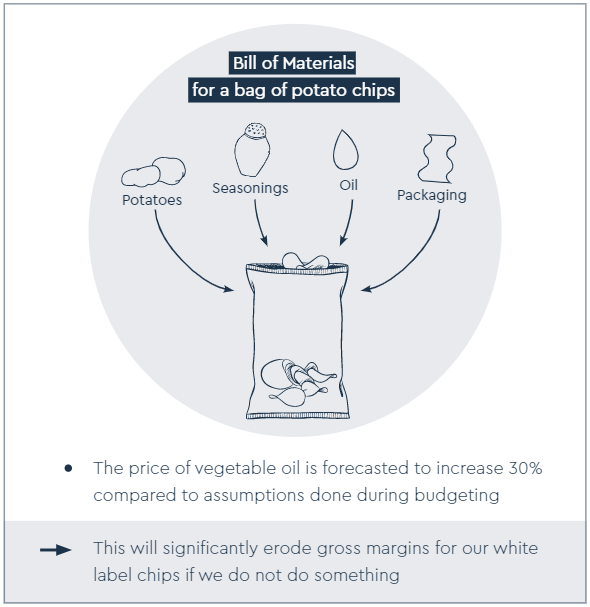

Let us use a bag of potato chips as an example. The picture below illustrates how vegetable oil price changes can impact gross margins for a potato chips manufacturer:

It is impossible to run a business in a fact-based manner without good visibility of expected material price developments. Unfortunately, creating good direct materials budgets and forecasts is far from easy.

Many companies are struggling to create even basic materials forecasts, let alone be able to fully benefit from all the insights that a world-class materials cost forecasting process can bring.

Creating Reliable Materials Forecasts is Challenging

Companies have well-established processes and systems for building revenue-side budgets and forecasts.

Typically, a dedicated Planning team or function is responsible for end-product demand planning and sales and operations planning activities.

These planning teams often use integrated tools and systems to carry out these activities. However, things tend to be much less robust when it comes to direct materials forecasting.

One of the main reasons for this is that while understanding end-product demand is the responsibility of a dedicated planning team, there is no comparison or dedicated entity to carry out materials forecasting activities.

Typically, the responsibility of conducting materials forecasting is on Finance’s turf. As Finance is responsible for the overall budgeting and forecasting processes, they also have an inherent interest and need for material cost forecasts.

A company with a dedicated Procurement Finance team is a natural home for the materials forecasting process. Finance responsibility regarding materials forecasting is two-fold:

However, Finance has little input into the actual content of the forecast and must rely on other functions to provide the needed data.

And here lies the challenge: even though the ownership of the process is transparent, getting reliable data into the budgets and forecasts is often a painful and resource-consuming process without a clear benefit for the parties involved.

Simple Process in Theory, Difficult in Practice

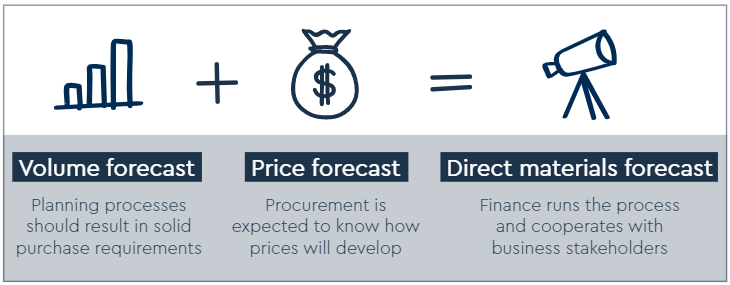

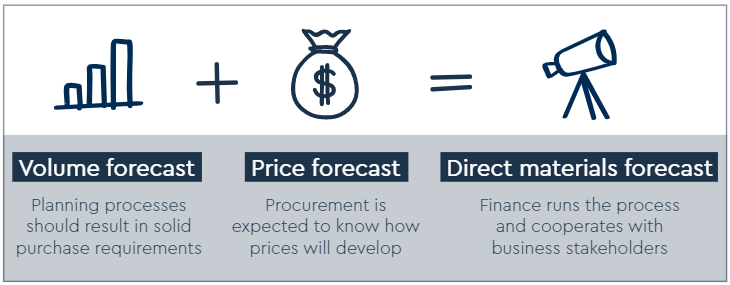

The premise of creating materials forecasts is simple enough: First, gather volume forecast data from existing ERP and planning systems. Then, with this accurate volume forecast data, the Procurement team can give solid predictions on the prices of the future materials.

Finance needs to combine this data, visualize, and review the results with business stakeholders.

However, in large global enterprises creating solid materials forecast is usually a daunting task. Good quality volume forecast data is not readily available from existing systems, and coming up with solid price forecasts for thousands of materials can be a real struggle for procurement organizations with their hands already full of other work.